Description

| Non-marring press fit top gasket |

| Wet and dry operation |

| Must be hard wired in the field |

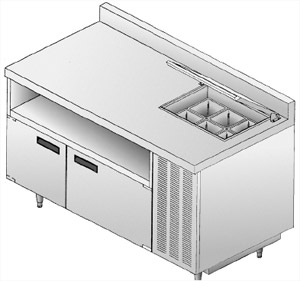

| Top is constructed of 18-gauge stainless steel |

| Galvanized exterior body |

| Flush mounted die stamped frawn 12″ x 20″ individual 20-gauge wells |

| Wells depressed slightly into the top to hold in condensation |

| Standard 1/2″ stainless steel drain(s) |

| 11.87” x 19.87” single hot food wells are manifolded together standard to one main gate valve |

| Unit shall be insulated on the bottom and all sides with 1” of fiberglass |

| Individual digital temperature controls standard wired to one main control panel with 4’ of conduit and wire. Field install control panel at location |

| Energy Savings Power wells (ESP) |

| Energy efficient 500 watt heat-pad per well |

| Top Top shall be one-piece 18-gauge stainless steel, with 0.65″ (2cm) overhang around perimeter and die-stamped 19.87″ x 11.87″ (50cm x 30cm) openings with depressed edges. Formed well below each opening shall be 6.25″ (16cm) deep. Each well shall have an individual digital temperature control and 500 watt heating element attached to bottom of well. Each well shall be equipped with a 0.5″ female N.P.T. drain located in right rear corner. All drains manifold to a 0.5″ gate valve at the left. Exterior housing shall be 20-gauge galvanized steel. Unit shall be insulated on sides, bottom and between wells with 1.00″ (2.5cm) fiberglass. |

| ESP Energy Saving Power wells (ESP) provided with individual solid state digital temperature controls wired to one main control panel with 4’ of conduit and wire. Each well is individually equipped with a 500 watt heated pad attached to bottom and sides of well. Unit shall have a three-wire electrical junction box to allow hard-wiring at installation. Electrical connections are 208-230V or 240V. |